As consumers, we often overlook the product design process, failing to appreciate how an idea becomes an actual product. Instead, we tend to focus on a product's functionality and price when making a purchase.

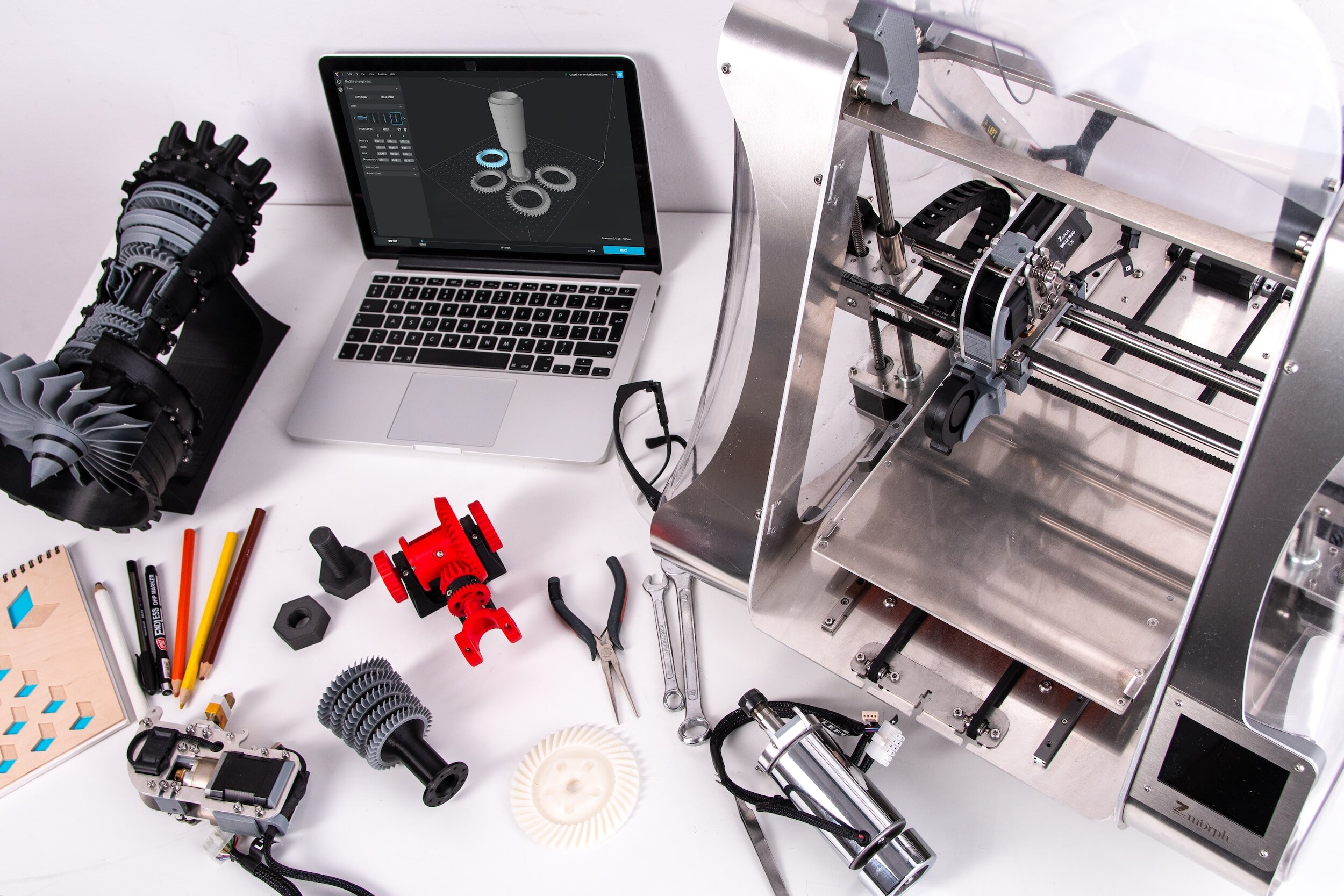

Prototyping is an evolving art, embracing new technologies and tools in the design process. It serves as the foundation of design. With 3D CAD modeling and rendering software, designers can generate lifelike representations of their creations. Product designers begin with a product idea, create sketches, 3D CAD models, and prototypes, refining their work until the product is production-ready. At the end of the day, nothing beats a physical product that can be held in your own two hands.

There are several reasons why a prototype has to be made during the design process.

Prototypes improve the overall understanding of the design

Most people are visual when it comes to understanding a concept or idea. Rapid prototypes services help illustrate the final product, allowing the design team to comprehend the product’s function, and target audience. A slight shift in proportions can make a huge difference and completely change the look and function of a product.

Minimise design error

If a product is near completion, making any drastic changes would create more work and increase the budget. By using prototypes, design teams can make changes early, reducing extra work and costs.

Allows for user testing

Every product has a target audience, and at the end of the day, the audience is going to have the final say. Prototypes allow for user testing, which provides designers with valuable feedback about their product. With their insights, the design team can make changes early on.

Improves team communication

Creating any product requires a team of designers that can effectively communicate their ideas and concepts with one another. When they have a physical product, it’s easier to provide feedback and see whether the product has a specific limitation. Prototypes ensure that the product they’re creating is serving its purpose.

Prototypes attract investors

A product’s goal is to be designed and then mass produced for consumers. It’s normal for a product to hit financial patches and require an expanded budget. If a product needs further investment, having a prototype is an attractive feature. Investors aren’t interested in spending money on a design that may work once it’s produced. They want to see the product in its physical form.

When it comes to picking materials for your prototype, there are a few things to keep in mind:

-

Cost

Budget is a big factor, as the materials can vary in price.

-

Durability

Some projects need strong and durable materials to handle the stress they'll face.

-

Functionality

Different materials have different properties, like insulating, shock-absorbing, or conducting electricity.

-

Cost

How you plan to make the final product can influence the material you choose for the prototype.

Different materials work best with different methods, so you have to choose wisely. Now, let's look at some common prototyping methods:

-

3D Printing

This builds a 3D object layer by layer from a computer design, making it efficient and low-waste.

-

CNC Machining

Precision is key here, but it can be more time-consuming and expensive.

-

Sheet Metal Fabrication

Metal parts are shaped through cutting, bending, and welding.

-

Cost

Great for mass production, it injects molten material into a mold.

-

Urethane Casting

Uses silicone molds to create plastic or rubber parts under vacuum

In conclusion, selecting the right materials and manufacturing process is crucial for creating successful prototypes. With advancements in technology, there's a wide range of materials available. Make sure your choice aligns with your project's specific requirements to ensure a smooth path from prototype to final product. If you have questions, our experienced team at hone.pd is here to help you make the right decisions for your project.

Download our free resources to find out more and start your product design journey.

Download: Product Design Playbook

Download: Value of Design & ROI Calculator